The suspension system of a car plays a major role in its working. The car’s suspension is directly related to the comfort a passenger can experience when driving his car. The suspension also ensures that the car is stable on the road and can be managed easily and effectively. Thus, even if a car’s performance in terms of its power and mileage is up to the mark, a bad suspension will result in a bad experience even then.

The main purpose of the car’s suspension is to absorb the bumps which one finds invariably on the roads we drive on. If these bumps would not be absorbed by a dedicated system, cars might even lose touch with the road when traversing the bump, leading to loss of control. Thus, the need arises for a suspension system.

The suspension system, though quite important for a car’s functioning, often does not receive as much attention as the other parts of a car do. Today, we take a look at the car’s suspension. What are its elements, and how does it all come together?

Though the suspension is a complicated mechanism, involving various elements of mechanics, we shall do our best to provide conceptual understanding of the various suspension components.

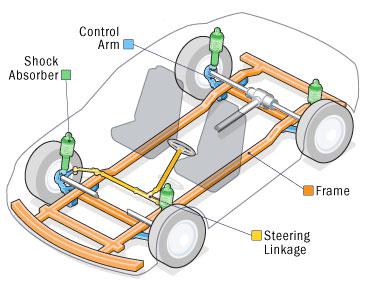

Before we start on the suspension, let’s take a look at the car frame first though.

Frames

The vehicle frame is the physical structure of the car that supports the car’s engine and body. The frame then rests on the vehicle’s suspension, which is the interface to the ground. To provide a rigid structural foundation for vehicle body and solid anchorage for suspension system, a quality frame is essential.

In general, two types of frames are distinguished in cars.

Framed construction

In the framed construction, all major parts of the vehicle are attached to a physical frame. The frame must provide support and strength needed by assemblies and parts attached to it.

Framed construction is used in almost all SUV vehicles such as Tata Sumo, Safari, Mahindra Bolero, Scorpio etc

Frameless or Unibody construction

This type of frame construction has no separate frame. The body is so constructed that the car’s body parts themselves supply the rigidity and strength required to maintain the structural integrity to car, thus forming the ‘frame’ themselves. The unibody construction significantly lowers the base weight of car and that in turn increases the mileage of car.

All hatchbacks and even many sedan cars make use of a unibody construction. To mention a few, Maruti 800, Alto, Swift, Tata Indica, Chevrolet Spark, Beat, and the sedans Swift dZire and Indigo etc. Clearly, where the car is less big, a separate frame may not be required.

The Car Suspension

In general, most of the automotive suspension systems have the same basic components and operate similarly. Their differences are found in the method in which the basic components are arranged.

The components found in any suspension system include springs, shock absorbers, torsion bars and other allied systems. Let’s take a look at them separately.

Springs

The spring is the core of nearly all suspension systems. It is the component that absorbs the road’s shock forces while maintaining correct riding height for the car. This is due to the fact that springs are pliable and return to their original shape, while they also resist change. If the car’s springs are worn out or damaged, the other elements shift out of their proper positions and are subjected to increased wear. The increased effect of shock will then impair vehicle’s handling.

Various types of springs are used in suspension system viz coil, torsion bar, leaf spring, air springs. All these springs are rubber mounted to reduce shock and noise.

Coil Springs

Two basic designs of coil springs are used - linear rate and variable rate

Linear Rate: These characteristically have one basic shape and a consistent wire diameter. All linear springs are wound from a steel rod into cylindrical shape with even spacing between the coils. As load is increased, the spring is compressed and coils twist (deflect). As load is removed, the coil flex (unwind) back to the normal position.

Variable rate: In thistype spring designs are characterized by a combination of wire sizes and shapes. The most commonly used variable rate springs have a consistent wire diameter, are wound in cylindrical shape and have unequally spaced coils. This type of spring is called a progressive rate coil spring.

Leaf Springs

Although leaf springs were the first type of suspension springs used on automobiles, today they are generally found only on light and heavy duty trucks, vans and some passenger cars. There are three basic types of leaf springs: Multi leaf, mono leaf and fiber composite. In general, a leaf spring is flat in shape rather than a coil as the more familiar spring.

Multi leaf: Multiple leaf springs consist of a series of flat steel leaves that are bundled tighter and held with clips or by a bolt placed slightly ahead of center of bundle. One leaf called main leaf runs the entire length of spring. The next leaf is a little shorter and attaches to main leaf. The next leaf is shorter and attaches to second leaf and so on.

This system allows almost any number of leaves to be used to support vehicle weight. It also gives progressively stiffer spring. It must be remembered that as spring flexes, the end of leaves slide over one another. This sliding can be a source of noise and can also produce friction.

Multi leaf springs have a curve in them, this curve if doubled forms an ellipse. Thus, leaf springs are sometimes called semi-elliptical or quarter-elliptical. The semi or quarter refers to how much ellipse the spring actually describes. The vast majority of springs are semi-elliptical.

Mono leaf spring: Monoleaf or single leaf springs are usually the tapered plate type with heavy or thick center section tapering off at both ends. This provides variable spring rate for smooth ride and good load carrying ability. In addition single-leaf spring does not have the noise and static friction characteristics of multi-leaf spring.

Fiber composite Springs: While most leaf springs are still made of steel, recent years have shown fiber composite type increasing in popularity (also called plastic springs). They are made of fiberglass, laminated and bond tighter by tough polyester resins. Long strands of fiberglass are saturated with resins and bundled tighter by wrapping or squeezed tighter under pressure.

Air Springs

Air Springs use an air-operated microprocessor controlled system that replaces conventional coil spring with air springs to provide a comfortable ride and automatic front and rear load leveling. The air springs are located in same positions where coil springs are usually found. Each spring consist of a reinforced rubber bag pressurized with air. The bottom of each airbag is attached to an inverted piston mount that reduces the interior volume of air bag during the ‘jounce’ (bounce in common words). This effect of increasing air pressure inside the spring as it is compressed makes it progressively stiffer.

Torsion bar Suspension system

In this system, the Torsion bar (read on later) serves the same function as coil springs. In fact this system is often described as straightened out coil springs. Instead of compressing like coil springs, a torsion bar twists and straightens out on the recoil. That is, as bar twists, it resists up-and–down movement.

Shock Absorbers

The second important component of the suspension is the shock absorber. The shock absorber is meant to damp or control the motion in a vehicle. If unrestrained, springs continue expanding and contracting after a blow until all energy of the road bump is absorbed. This would lead to a rough and unstable ride after consecutive shocks.

Working

While the physics of the shock absorber are quite complex, in a nutshell the shock absorber takes the mechanical energy of the spring and converts this into heat energy. It does this by offering resistance to the springs – the spring’s expansion and contraction is connected directly to the shock absorber. The resistance is due to the oil present in the shock which obviously is hard to compress.

Conventional hydraulic shocks are available in two styles: single tube and double tube. The vast majority of domestic shocks in India are double tubed. While they are a little heavier and run hotter than single tubed type, they are easier to make. The double tube shock has an outer tube that completely covers inner tube. The area between tubes is the oil reservoir. A compression valve at bottom of inner tube allows oil to flow between the tubes. The piston moves up and down inside the inner tube. This flow and increased heat of the oil reduces the energy of the springs.

In a single monoshock, there is a second floating piston near the bottom of tube. When fluid volume increases or decreases, the second piston moves up and down compressing the reservoir. The fluid moves back and forth between reservoir and main chamber. There are no other valves in single tube shock besides those in main piston. The second piston prevents oil from splashing around too much and getting air bubbles in it.

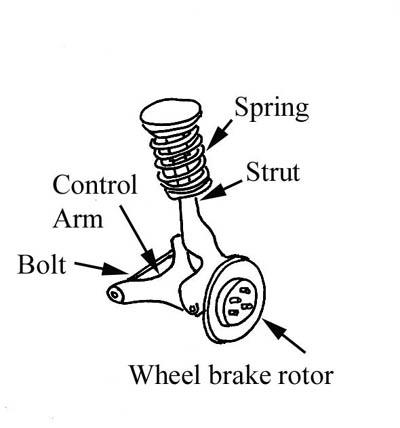

MacPherson struts

You must have heard of the MacPherson strut, which is present in many modern day cars. In a MacPherson strut, the spring and shock absorber is combined into one single assembly. Its most distinctive feature is thus the combination of the main elements into single assembly.

Interestingly, by inserting the shock into the spring it now provides the function of the shock absorber, but also increases the stability of the suspension as it is now part of the car’s physical system. In fact, the strut provides damping function of shock absorber, in addition to serving to locate the spring and to fix the position of the suspension.

The Torsion / Anti-Sway Bar

The above mentioned systems are independent per wheel on the car – the springs, which are attached to the wheel, vibrate independently from each other. The anti-sway or torsion bar connects the two sides of the car together – along the axis. As a result, mechanical energy from one side of the car is transferred to the other side, thus reducing the impact of the bumps. The car’s drift is reduced and a more level ride is created.

Suspension Mounting

The suspension elements - springs and shocks – are attached in series to the wheels. These of course need to be attached to the frame, so that there is support for the car. In frame suspensions, suspension’s connected to the frame with so-called arms. The control arm serves as the lower locator for suspension.

In frameless cars, the connections are made directly onto the body shell. The strut would be on the upper portions and lower arms are on the lower part of the shell.

Differences between front and rear suspensions

As explained before, the car finds suspension systems in all four wheels of the car. The suspension needs differ a bit in the front and back.

Front suspension

Front suspension systems are fairly complex. They have somewhat contradictory jobs. They must keep the wheels rigidly positioned and at the same time allow them to steer right and left. In addition, because of weight transfer during braking, the front suspension absorbs most of braking torque. While accomplishing this, it must provide good ride and stability characteristics.

As discussed earlier most independent suspension system have same basic components and operate basically in the same manner as already described. The system differs only in the way components are arranged and tuned. Thus, the tuning for the front will differ from the rear suspension.

Rear suspension systems

There are three basic types of rear suspensions: live axle, semi independent, and independent. There are distinct designs of each, but the types of components and principles involved are the same as on front suspension systems.

Live Axle rear suspension system: This traditional rear suspension system consists of springs used in conjunction with a live axle (one in which differential axle, wheel bearings, and brake act as a unit). The springs are either of leaf or coil type.

Semi independent suspension: A coil spring and shock absorber strut assembly are ordinarily used with this suspension system. The bottom of strut is mounted to rear end of trailing arm. Braking torque is transmitted through the trailing control arms and strut. The arm and struts also maintain force and positioning of wheels.

Independent suspension: In this type, coil springs are used between control arm and vehicle body. The control arms pivot and are attached at other end to spindle. A shock absorber is attached to spindle or control arm.

Electronically controlled suspensions

Advances in electronic sensor and computer control technology have led to a new generation of suspension systems. The simplest systems are level control systems that use electronic height sensors to control an air compressor linked to air-adjustable shock absorbers.

More advanced adaptive suspensions are capable of altering shock damping and ride height continuously. Electronic sensors provide input data to a computer. The computer adjusts air spring and shock damping settings to match road and driving conditions

Conclusion

The above are the brief details and working principle used in different types of suspension systems. There is a consistent improvement in technology used in suspension systems as indeed it is one of the key determinants of car comfort.

As a close, it’s interesting to note how you will experience different suspensions between cars. A simple leaf spring suspension won’t give you the comfort of an independent suspension system and will thus be much rougher to drive in. The ‘bounce’ between the suspensions differs. For example, a racecar will have a very stiff suspension – meaning tighter springs – which make you experiences bumps in the road much more, but will also allow the car to be handled much more aggressively as the vehicle sway will be limited. Luxury sedans will have looser springs, which means you will not experience bumps as much, but will need to be more careful while maneuvering.

Finally, it may be time to check out your suspension in case you experience frequent screeching sounds while driving on rough roads