Over the last few weeks, we have covered various parts of the car, including transmission, suspensions and engine fluids. While transmission is connected to accelerating and moving the car, and suspensions are related to a smooth drive, another key system is the braking system, which as we all know serves to stop the car. Today we check out the car’s braking system. Do share your comments and feedback.

Brakes are one the key parts of any vehicle, without which it is virtually not possible to use the vehicle for travel. Clearly, a brake, which serves to slow down the vehicle, should not be too weak. But interestingly, when designing a brake system, it should also be taken care that it’s not too efficient. A too strong a brake would expose us continuously to the ill effects of a sudden brake application in bus or car. If a vehicle is stopped abruptly or strongly, the passenger may hit the front seat or whatever is there. Hence, too efficient a brake system is not required!

The braking system is strongly relation to Newton’s laws of motion. Indeed, the above phenomenon is linked to Newton’s second law of motion, which states “A body continues to be in its state of rest or of motion unless external force acts on the same”.

On the other hand, if a brake system is too weak, the stopping distance would increase and hence may lead to accidents. Thus, a brake system should be perfect enough to stop the vehicle at minimum safe distance, without affecting the comfort of the passenger. In an endeavour to achieve this there have been a lot of developments in the brake system technology, right from Mechanical brakes to Air brakes in automobiles. In this article we would like provide the relevant information regarding the same

Braking – fundamentals: friction and how it applies to automobiles

A brake system is designed to slow and halt the motion of vehicle. To do this, various components within the brake system must convert vehicle’s moving energy into heat. This is done by using friction.

Friction is the resistance to movement exerted by two objects on each other. Two forms of friction play a part in controlling a vehicle: Kinetic or moving, and static or stationary. The amount of friction or resistance to movement depends upon the type of material in contact, the smoothness of their rubbing surfaces and the pressure holding them together.

Thus, in a nutshell a car brake works by applying a static surface to a moving surface of a vehicle, thus causing friction and converting kinetic energy into heat energy. The high-level mechanics are as follows.

As the brakes on a moving automobile are put into motion, rough-textures brake pads or brake shoes are pressed against the rotating parts of vehicle, be it disc or drum. The kinetic energy or momentum of the vehicle is then converted into heat energy by kinetic friction of the rubbing surfaces and the car or truck slows down.

When vehicle comes to stop, it is held in place by static friction. The friction between surfaces of brakes as well as the friction between tires and roads resist any movement. To overcome the static friction that holds the car motionless, brakes are released. The heat energy of combustion of in engine is converted into kinetic energy by transmission and drive train, and the vehicle moves.

Types of brakes

There are basically three types of brakes used in automobiles

1. Mechanical brakes

2. Hydraulic brakes

3. Air Brakes and related type of brakes

Mechanical brakes

Mechanical brakes are used in Hand brakes (or parking brakes). Here, a lever is provided near the driver seat and through steel wire connections it is connected to brakes at the rear of the vehicle.

When the hand brake is engaged, tension is created at the brakes and the brake shoe holds the drum from rotating and hence the movement of the vehicle is restricted, even if parked in a slightly inclined surface.

Hydraulic brakes

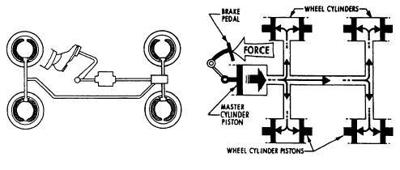

The hydraulic brake system uses brake fluid to transfer pressure from the brake pedal to the pads or shoe. By exercising the pedal, brake fluid transfers this pressure to the brake pads. This transfer of pressure is reliable and consistent because liquids are not compressible, i.e. pressure applied to liquid in a closed system is transmitted by the liquid equally to every other part of system.

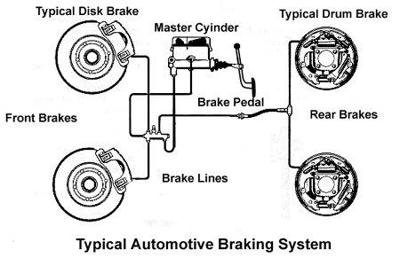

A hydraulic brake system apart from liquid pipes mainly consists of Brake pedal, Master cylinder, wheel cylinder and brake pads/shoe connected at the wheel. The function of the Master cylinder is to distribute pressure to lines leading to front or rear wheels as required. At the wheel cylinder, a small piston is provided which is operated due to pressure application through brake fluid. The operation of the piston is converted to movement of brake liners.

In brief, when a driver applies pressure at the brake pedal, the mechanical force (stepping of driver on pedal) is changed to hydraulic pressure which is transmitted through liquid to respective wheel cylinder and changed back to mechanical force (operation of brake pads, shoe).

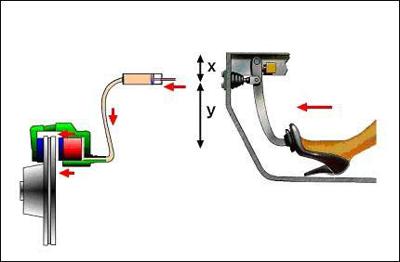

Power Brakes

Power brakes are nothing more than a standard hydraulic brake system with a booster located between the brake pedal and master cylinder to help activate the brakes. This could be in case the fluid pressure required would be too high.

There are two basic types of power assisted mechanisms used, vacuum assisted and hydraulic assisted.

Vacuum assisted system use engine vacuum pressure to help apply the brakes.

Hydraulic assist is largely found on heavy vehicles. This system uses hydraulic pressure developed by the power steering pump or other external pump to help apply the brakes.

Air brakes

Air brake system consist of components like air compressor, air reserve tank, check valves, safety valves etc. The working is very similar to the working of hydraulic brakes. The key difference is that mechanical force is transmitted to wheel ends through air pressure, instead of fluid pressure. Airbrakes are most preferred in heavy vehicles.

Disc vs Drum Brakes

Another brake classification is in terms of disc and drum. This refers to the actual mechanics of slowing down the vehicle. Let us take a look at these two systems.

Drum brakes

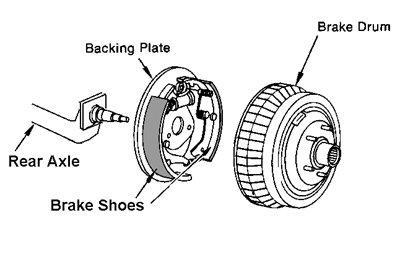

A drum brake assembly consists of a cast-iron drum which is bolted to and rotates with the vehicle’s wheel, and a fixed backing plate to which the shoes, wheel cylinder, automatic adjusters and linkages are attached. Additionally, there might be some extra hardware for parking brakes.

The shoes are surfaced with friction linings, which contact the inside of drum when brakes are applied. The shoes are forced outward by piston located inside the wheel cylinder. As drum rubs against shoes, the energy of the moving drum is transformed to heat. This heat energy is passed into the atmosphere. When brake pedal is released, hydraulic pressure drops and the shoes are pulled back to their unapplied position by return springs.

Disc brakes

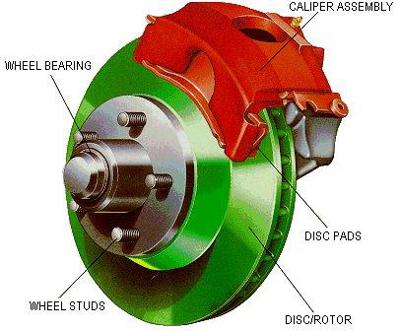

In disc brakes the friction elements are in the form of pads, which are squeezed or clamped about the edge of a rotating wheel. With automotive disc brakes, there is a separate wheel unit called the Rotor (commonly called as disc) alongside the vehicle’s wheel. This rotor is made of cast iron. Since pads clamp against both sides of it, both sides are machined smooth. Usually the two surfaces are separated by a finned center section for better cooling (such rotors are called ventilated rotors or in common words as ventilated discs).The pads are attached to metal shoes, which are actuated by pistons, the same as with drum brakes.

The pistons are contained within a caliper assembly, housing the wraps around the edge of the rotor. The caliper is kept from rotating by way of bolts holding it to the car’s suspension frame work.

Unlike shoes in a drum brake, the pads here act perpendicular to the rotation of disc when brakes are applied. The effect is different from that produced in a brake drum, where frictional drag actually pulls the shoe in to drum. Disc brakes are said to be non-energised and so require more force to achieve the same braking effort. For this reason, they are ordinarily used in conjunction with power brake unit.

In general, disc brakes are considered to be more effective than drum brakes. However, they are more complicated and hence come at a higher cost

Stop Light Switches

When exercising a brake, light starts burning on the back of the vehicle. The stop light switch and mounting bracket assembly is attached to the brake pedal bracket and is thus activated by pressing the brake pedal.

Brake bleeding

Fluids cannot be compressed, however gases are compressible. If there is any air in a fluid brake hydraulic system, this will be compressed as pressure increases. This action reduces the amount of force that can be transmitted by the fluid. This is why it is important to keep all bubbles out of the hydraulic system. To do this, air must be released from brakes. This procedure is called bleeding of brake system.

The simple procedure involves forcing of fluid through brake lines and out through a bleeder valve or bleeder screw. The fluid eliminates any air that may be in the system. Bleeder screws and valves are fastened to wheel cylinder or caliper. The bleeder must be cleaned. A drain hose is then connected from bleeder to glass jar where the fluid coming out from bleeder valve is collected. Bleeding involves repetition of procedure at each wheel to ensure complete bleeding.

Meanwhile, one person should also be assigned to top up the fluid level in container over master cylinder to compensate for the fluid taken out through valves. If top up is not continued, then there are chances of air bubbles being developed in system which further delays the process.

Antilock Braking system

When a driver quickly and firmly applies the brake and holds the pedal down, the brakes of a vehicle that is not equipped with ABS will almost immediately lock the wheels. The vehicle slides rather than rolls to a stop. During this time, the driver also has a difficult time keeping the vehicle straight and the vehicle might skid out of control. Here, the skidding and lack of control is caused by locking the wheels. If the driver could release the brake pedal just before the wheel locked up and then reapply brakes, the skidding could be avoided.

This last thing is exactly what an antilock system does. When the brake pedal is pumped or pushed, the pressure is quickly applied and released at the wheels. This is called Pressure Modulation. Pressure modulation works to prevent wheel locking. Antilock brake systems can modulate pressure to the brakes as often as 15 times per second. By modulating the pressure to brakes, the friction between tires and road is maintained and vehicle is able to come to a controllable stop.

Steering is another important consideration for the use of ABS. As long as a tire does not slip, it goes only in the direction in which it is tilted. But once it skids, it has little or no directional stability. One big advantage of ABS, therefore is the ability to keep control of vehicle under all conditions.

Trouble shooting

The table below gives the list of frequent troubles with brake systems, cause and remedy for the same.

| Sl no | Problem | Probable cause | Remedy |

| 1 | Loss of brake efficiency | Oil soaked Brake drum/liner | Check and replace wheel cylinder,liners |

| Worn out brake lining | Replace | ||

| Defective master cylinder | Service/replace | ||

| 2 | Brake binding | Brake shoe retracting springs weak | Replace |

| Defective wheel cylinder | Replace | ||

| 3 | Brake overheating | As in brake binding and with prolonged usage | Replace |

| 4 | Brake Judder | Wrong brake adjustment | Adjust |

| Loose lining rivets | Replace | ||

| 5 | Vehicle pulling to one side | Improper adjustment of linings | Adjust |

| Oil or grease settled onliners | Replace | ||

| 6 | Hand brakes ineffective | Stretching of operating cable | Replace |

| 7 | Excessive loss of brake fluid | Leaking master cylinder or wheel cylinder or hose joints | Service/replace |

| 8 | Excessive air bubbles | Defective master cylinder | Replace |

Conclusion

Brake system is an important mechanism for usage of any vehicles. The above is an attempt to give the relevant information in as simple manner as possible. There are much technical concepts used in designing of brakes which is beyond scope of the article. All are welcome to post relevant queries and comments. We would answer the same.